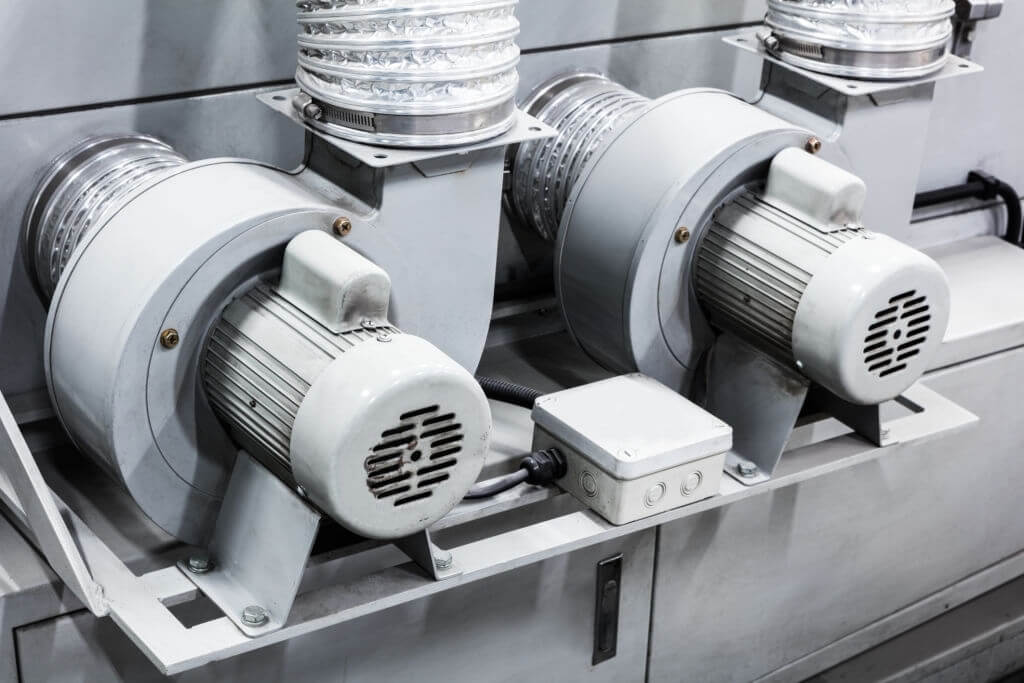

Every modern housewife uses a vacuum cleaner to clean her house or apartment. Even the highest quality vacuum cleaners fail over time and cease to perform their main function. One of the most common causes of vacuum cleaner breakdowns is the failure of the motor armature. In this article, Appliance Repair in Irving, TX experts will analyze in detail what a vacuum cleaner motor anchor is and explain how to replace a failed unit.

Engine anchor

Despite the fact that most vacuum cleaners perform a single task – removing debris and dust, the design of electric motors is quite complicated. Almost all electric motors of modern vacuum cleaners consist of the following parts:

- Stator housing;

- brush knot;

- Stator winding;

- Brush fixing screw;

- collector plates.

The armature of the vacuum cleaner motor is subjected to load more often than other units, so its service life is much lower. You can determine the malfunction of the engine armature by the following signs:

- Strong vibrations of the vacuum cleaner body during operation;

- The sound of the armature rubbing against the walls of the motor;

- The appearance of sparks during the operation of the vacuum cleaner;

- Heating of the case, and as a result, the appearance of an unpleasant smell of burnt plastic.

If you find such problems, it is imperative to repair the vacuum cleaner.

How to replace the motor armature of a vacuum cleaner?

In the event of a breakdown of this element of the engine, it is not at all necessary to carry the vacuum cleaner for repair, and even more so to buy a new one. If you wish, you can replace the failed anchor yourself. As a rule, when noise and vibration appear in the operation of the vacuum cleaner, it can be said with certainty that the motor armature has become unusable. Before going to an electrical parts store for repairs, it is worth disassembling the body of the vacuum cleaner and checking the condition of all elements. Some of the malfunctions that led to the breakage of the anchor can be corrected by the following methods:

- When carbon deposits appear on engine elements, cleaning agents must be used;

- Large scratches on the stator can be carried out by turning the surface;

- The appearance of vibrations of the vacuum cleaner means the failure of the rotor bearings. The problem is solved by a complete replacement of the element, or its repressing.

Another common problem that occurs in the operation of the vacuum cleaner is the wear of the coils. With proper skill, you can rewind the coil yourself. The application of turns must be carried out in accordance with the factory “coils” of wire. The section must match the factory wire, otherwise, the speed of the motor will be changed, which will lead to its breakdown.

Verdict

There are a variety of issues that we deal with on a daily basis. Many local companies have been offering their services in their area like Drywall Repair in St Petersburg, Florida, Interior Painting in Sarasota, Florida, and many others. They have been satisfying many clients and easing their lives for many years. If you don’t like all the hassles for your household repairs, you can hand over your worries to them and they will take the challenge and their service will meet your expectations.